Our partnership doesn’t end at hand‑over—it evolves. For more than 50 years we’ve engineered finishing systems that out‑perform and out‑last.

Our dedicated support team makes sure they stay that way, maximising uptime, energy efficiency and return on investment.

Every production line is different, so our service agreements adapt to your workload – from single annual health‑checks on your spray booths or industrial ovens to full quarterly deep‑dives on complete turnkey lines.

Factory‑trained engineers arrive with certified test equipment, OEM spares and a checklist built for your exact booth, oven or conveyor.

Routine visits spot wear before it becomes downtime, letting you plan repairs or upgrades during natural pauses in your production cycle.

Stay audit‑ready with a single visit that covers:

Certificates are issued on the day and stored in our secure client portal for easy retrieval. Where readings drift, engineers make airflow tweaks on site so you leave compliant and energy‑optimised.

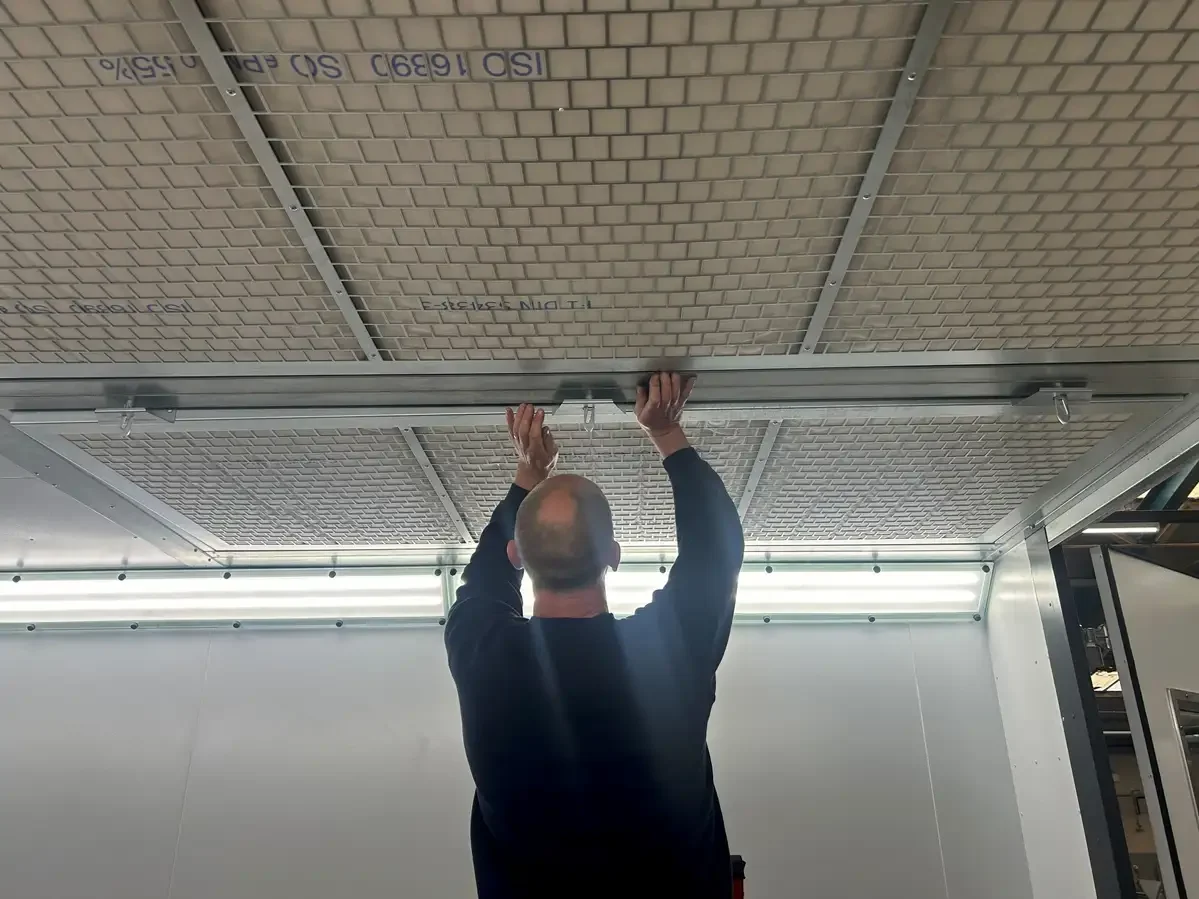

Clean media is the most cost‑effective way to protect finish quality and fan performance.

We hold bulk stocks of intake, extract and arrestor media at our Burntwood factory, ready for 24‑hour dispatch.

Add filters to your maintenance agreement or order ad‑hoc in minutes through our online spares store to keep inventory lean.

A stopped line loses profit every minute.

Call our desk and an engineer is on the road – promptly – often arriving the same day – with diagnostics and the OEM parts most often needed to achieve a first‑time fix on spray booths, curing ovens and conveyors.

For harder‑to‑source items we tap our network of legacy suppliers, keeping even 20‑year‑old systems in service.

Unitech Machinery has over 50 years of experience in paint finishing equipment and custom solutions to elevate your production with cutting-edge technology. CONTACT US now to boost your business efficiency and quality.